Provire combines technical expertise with years of experience in designing Operator Interfaces. From our beginnings with UNIX systems to our work since 2004 with the ABB Ability™ System 800xA, we deliver advanced and dynamic solutions for process visualization.

Dynamic Visualizations with ABB Ability™ System 800xA

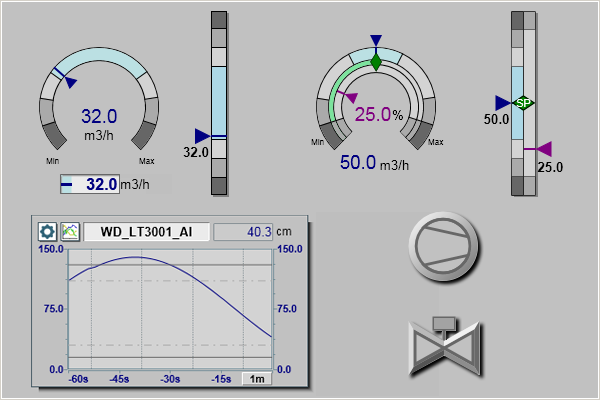

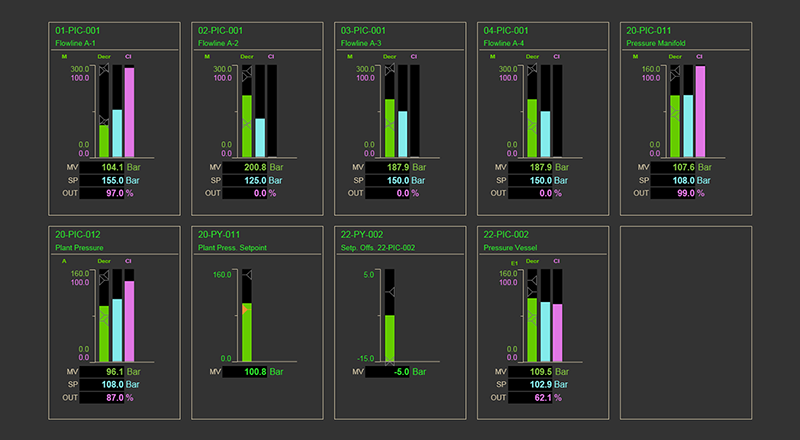

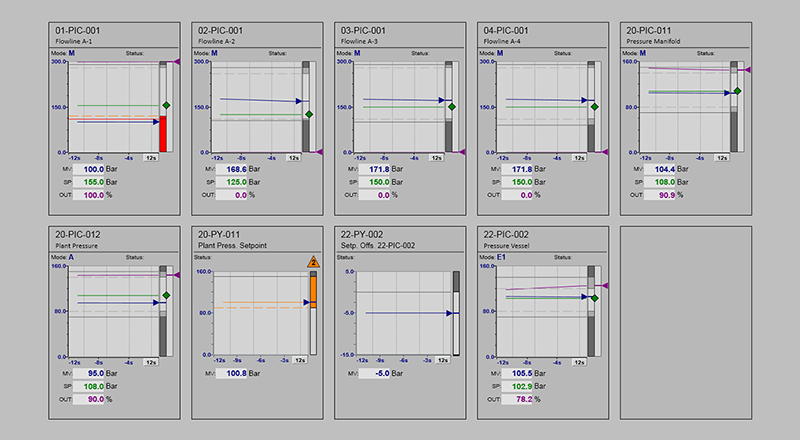

Unlike technical drawings, operator interfaces require a dynamic approach. We develop our interfaces using Process Graphics 2 (PG2), a vector-based graphical platform specifically designed for process visualization within the ABB Ability™ System 800xA. With PG2, we create advanced graphical elements that provide an intuitive and efficient presentation of process data.

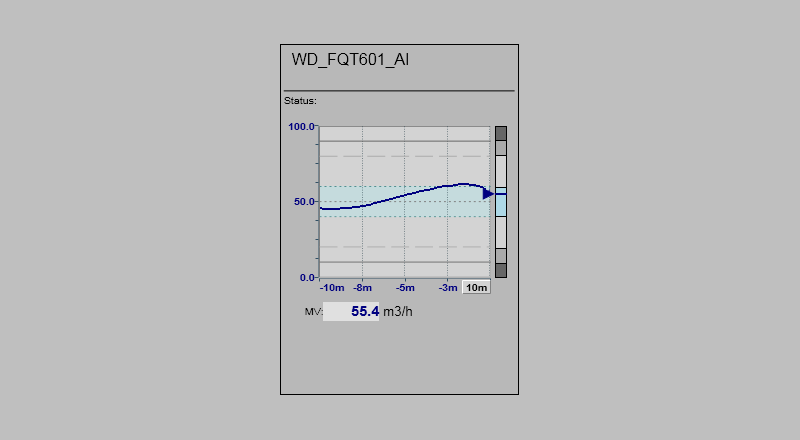

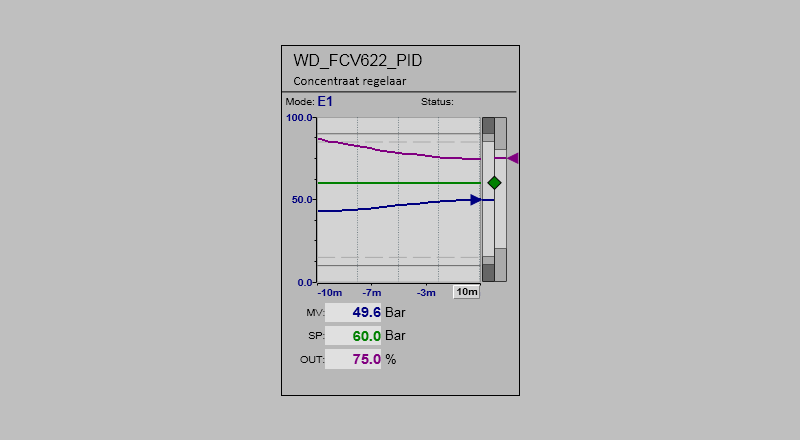

The strength of the ABB Ability™ System 800xA lies in its object-oriented structure. By leveraging the .NET framework and the C# programming language, we develop reusable, maintainable, and dynamic process visualizations. Examples include real-time color changes, dynamic graphs, and numerical displays that offer operators immediate insights.

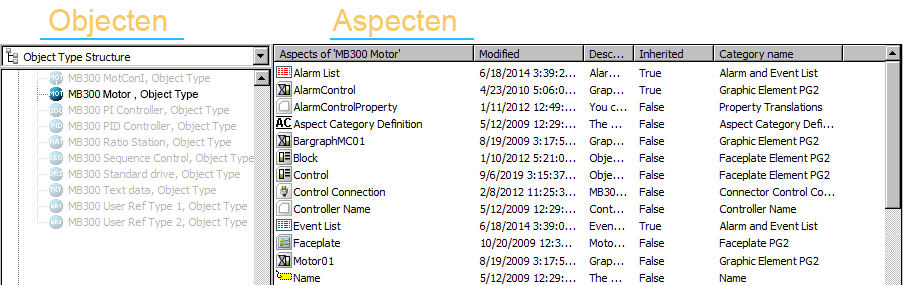

What is an Object?

An Object in the ABB Ability™ System 800xA represents a physical or logical component of the system, such as a pump, valve, or process module. Objects are based on a type, contain specific properties, and are managed within the Object Type Structure. Any changes made to objects in this structure are automatically applied to all associated structures, ensuring efficient management.

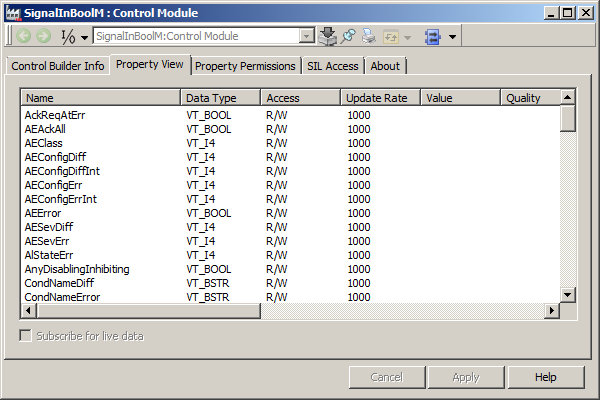

What is an Aspect?

An Object consists of various Aspects, each of which adds additional functionality or information. Aspects are modular and can be modified without altering the Object itself. Examples include:

- Control Aspect: Controls the Object, for instance, switching a pump on or off.

- Visualization Aspect: Displays graphical interfaces, such as process diagrams.

- Diagnostic Aspect: Provides status information, such as error messages and maintenance data.

- History Aspect: Tracks trends and alarm histories.

- Configuration Aspect: Contains parameters and settings for the Object.

The ABB Ability™ System 800xA includes extensive libraries of ready-to-use Objects and Aspects. These can be used directly or customized for specific processes. To ensure that modifications are preserved during standard software upgrades, the objects are first copied before being edited.

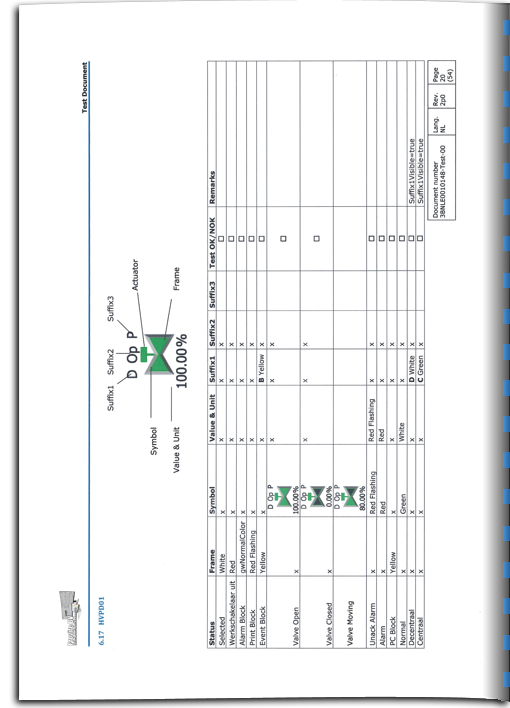

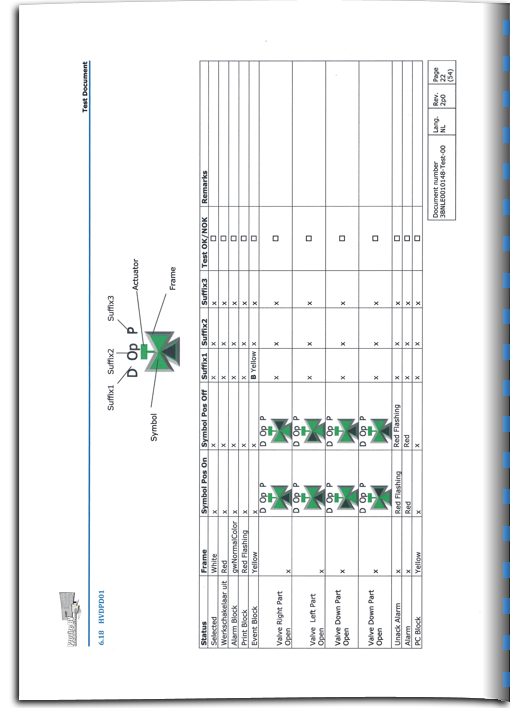

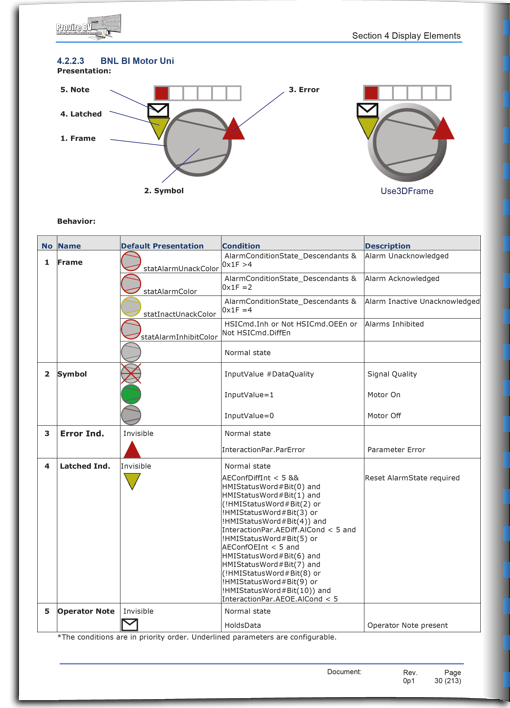

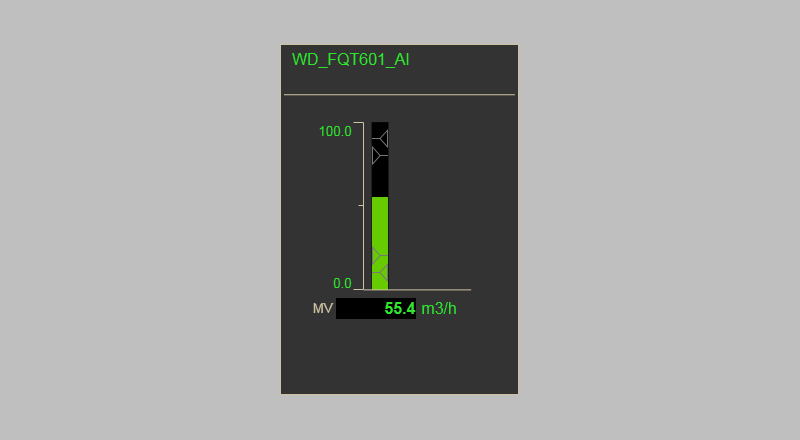

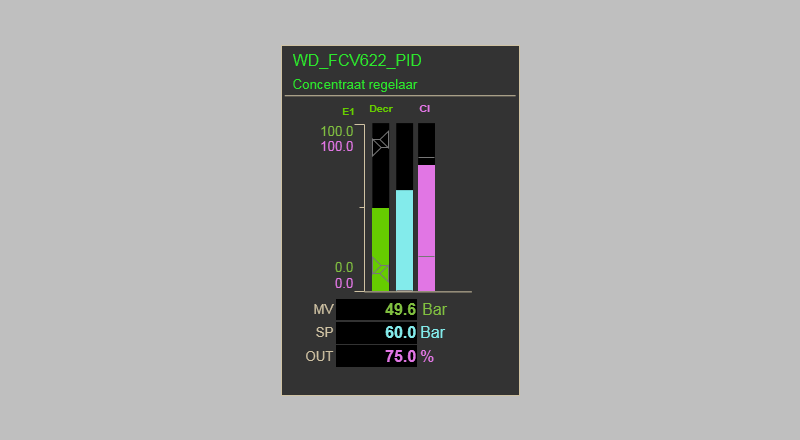

Provire also develops custom libraries with Graphic Toolbox Item Types. These graphical objects, such as Display Elements, are dynamically linked to process data and provide clear visualizations of sensors, actuators, and other equipment.

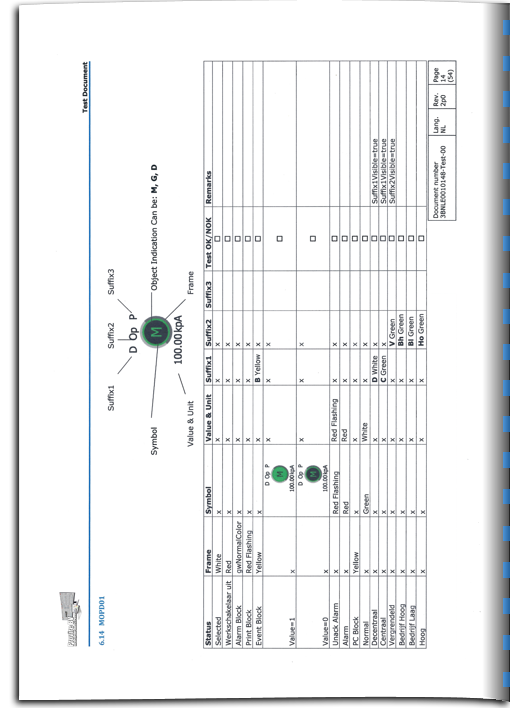

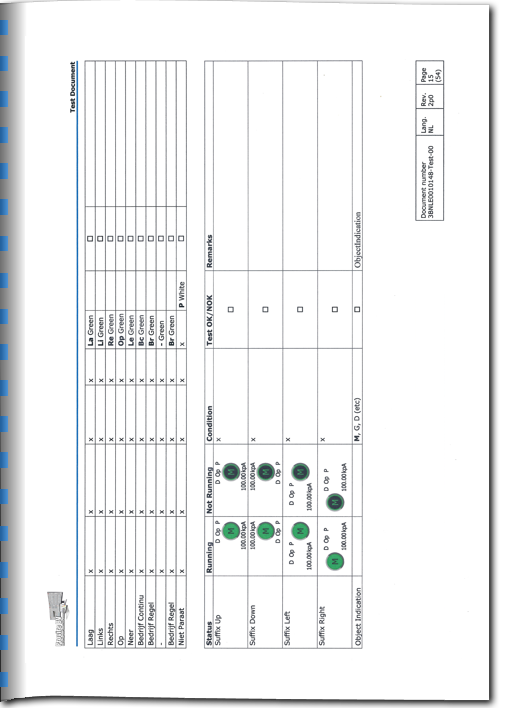

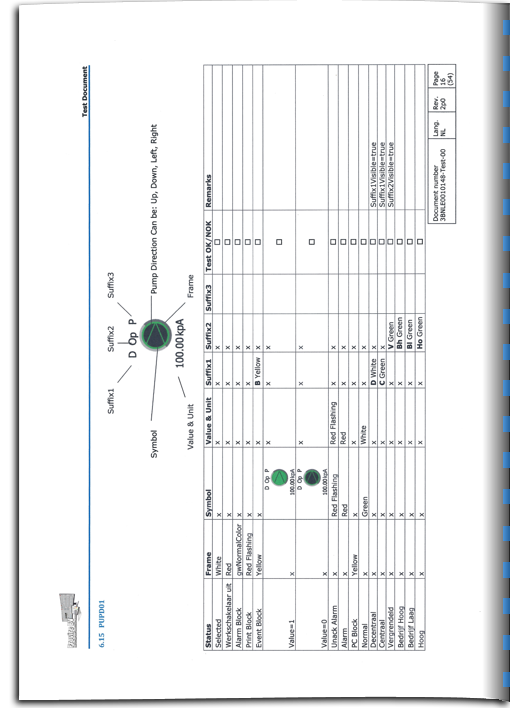

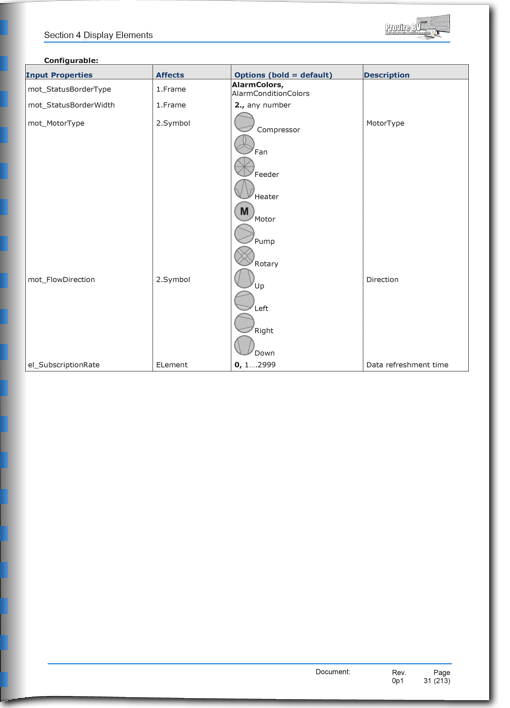

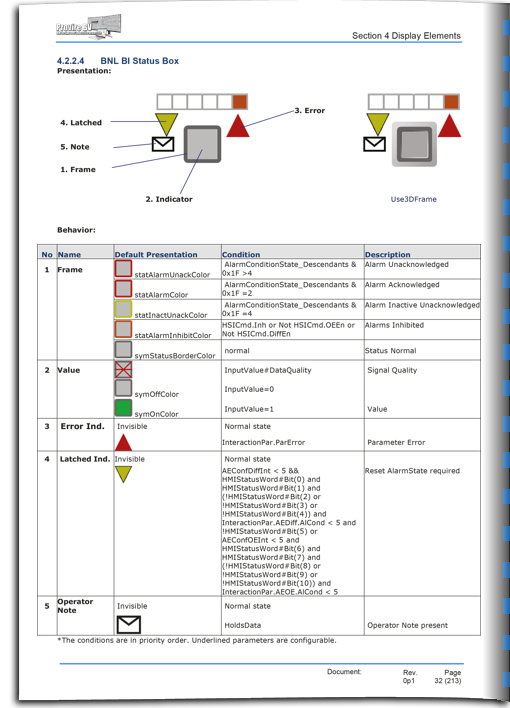

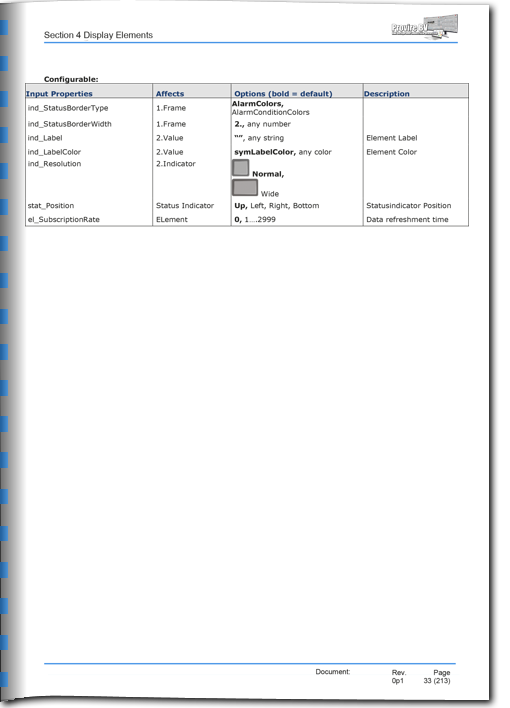

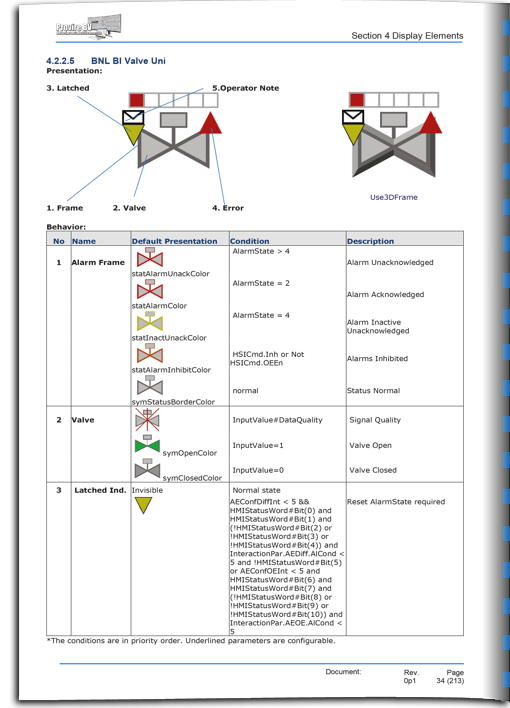

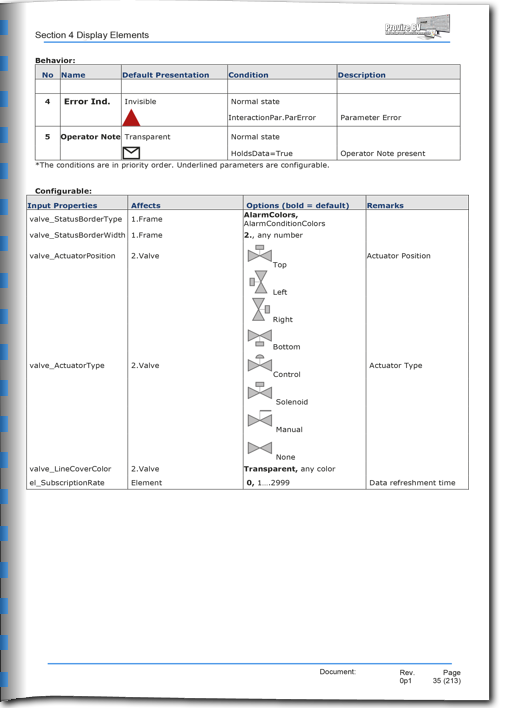

Display Elements:

Display Elements are graphical representations of components such as pumps and valves.

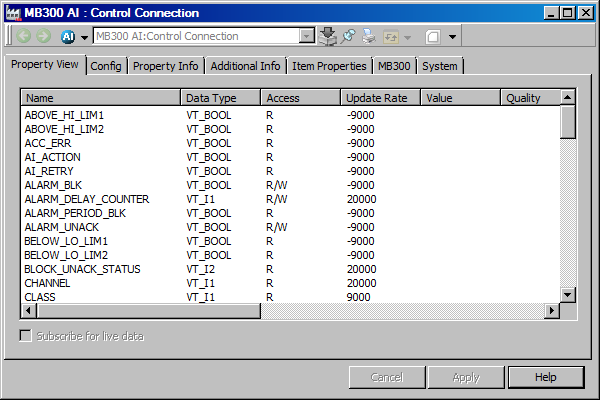

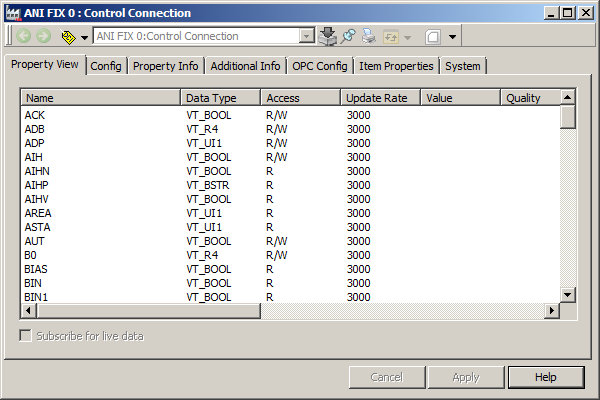

Using input properties, they are linked to the control module via code (.NET). This enables intuitive interaction and straightforward status monitoring.

Acontrol modulegenerates and manages data such as process values, statuses, alarms, and setpoints. This data is made available for presentation through OPC (OLE for Process Control).

IT Objects:

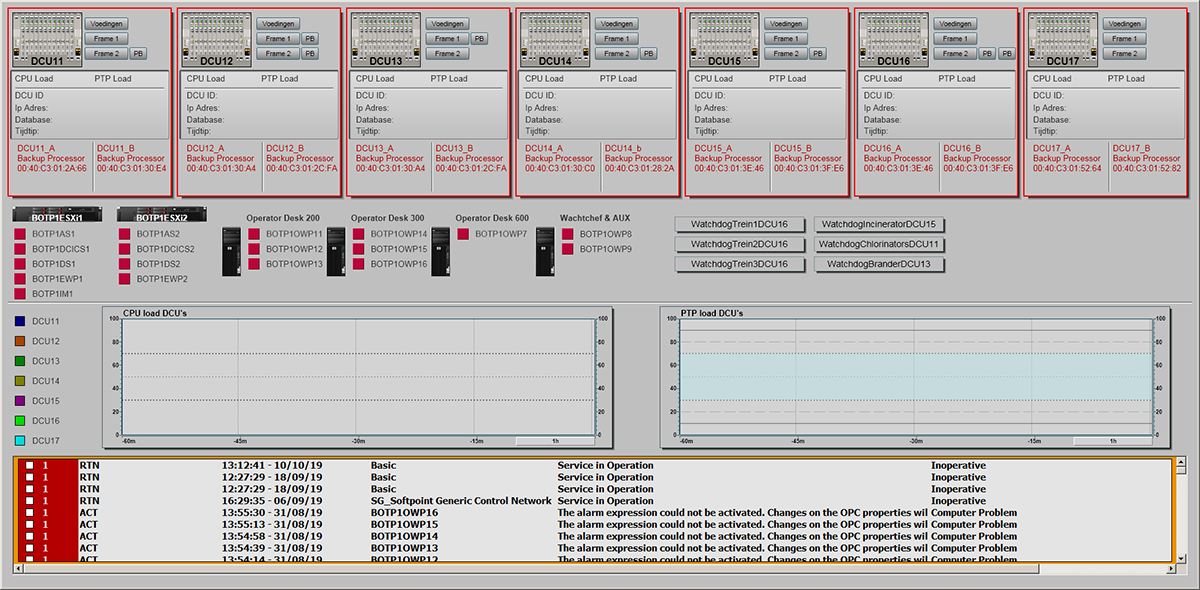

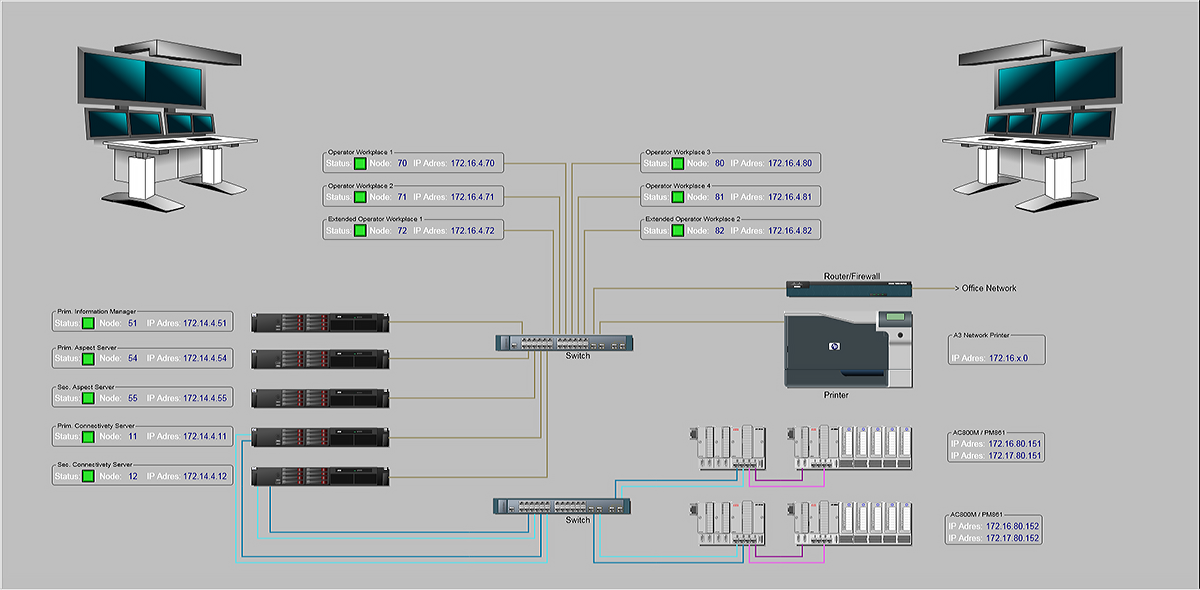

The IT Objects library contains graphical representations of control and system hardware and is used to display the system's status. They provide additional information, such as datasheets and I/O status, accessible via a context menu or faceplate.

Project Specific Objects:

For unique processes, we design objects that present real-time animations of the process.

For example, check out our demo of the storm surge barrier.

With modern software and hardware, we can create visualizations that help operators detect abnormal situations at an early stage. Unfortunately, existing libraries are often not fully utilized.

For various processes, object libraries are available, but in most cases, the display elements within these libraries are copies of those developed over 20 years ago, based on the capabilities of that time.

Provire develops new display elements based on the ANSI/ISA-101 standard. This enables more efficient and insightful process visualization, leading to improved decision-making and process optimization.

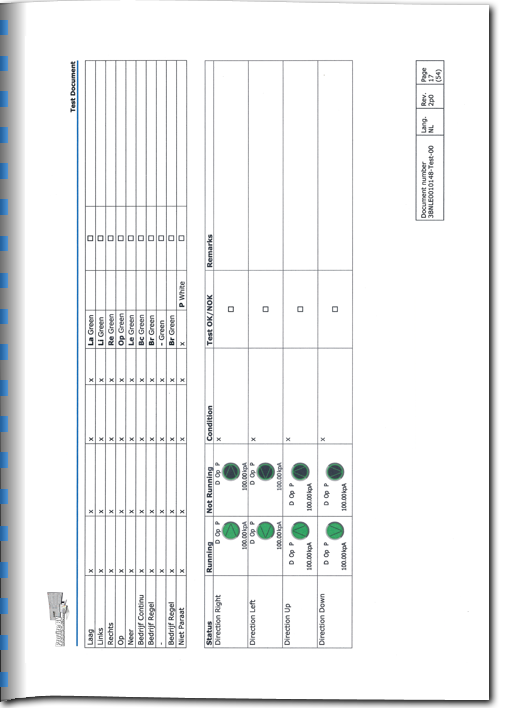

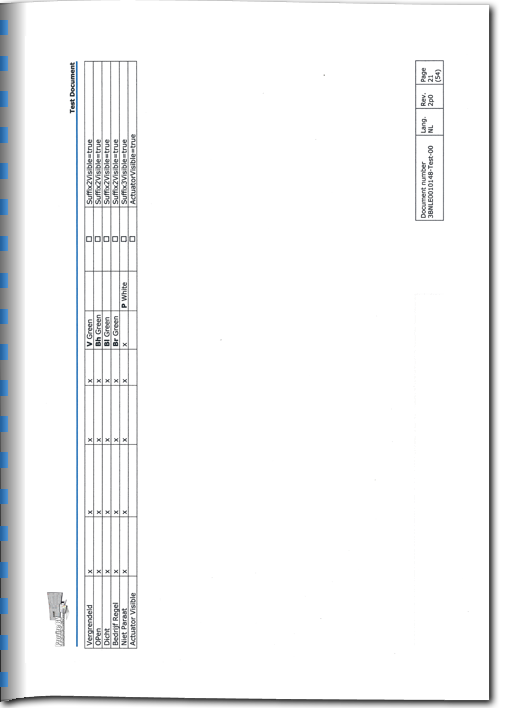

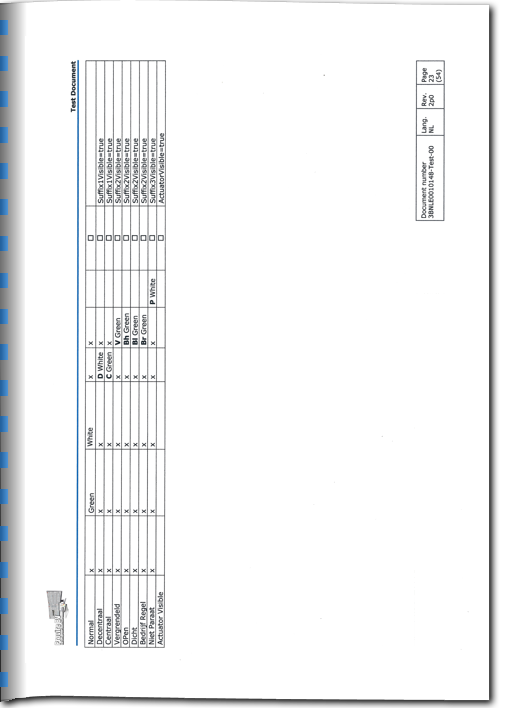

All Display Elements developed by Provire are thoroughly tested and documented in a test document. Together with our clients, we review this document to ensure functionality. Once approved, the Display Elements and their features are detailed in a reference manual.

With Provire, you choose quality, innovation, and a reliable partner in process automation.