ANSI/ISA-101

Colors should be used consequently. There are several types of common color-detection deficiencies in people, particularly males (red-green, white-cyan, green-yellow). For this reason, there is a well-known principle for the use of color: Color, by itself, is not used as the sole differentiator of an important condition or status.

Most graphics throughout the world violate this principle. Redundant coding of information using additional methods other than color is desirable. A color palette must be developed, with a limited number of distinguishable colors used consistently.

Bright colors are primarily used to bring or draw attention to abnormal situations, not normal ones. Screens depicting the operation running normally should not be covered in brightly saturated colors, such as red or green pumps, equipment, valves etc.

It is important to properly show the current condition of equipment that can have multiple operational states. State depiction should not depend on color but upon fill status, shape or even simple text.

When alarm colors are chosen, such as bright red and yellow, they are used solely for the depiction of an alarm related condition and functionality and for no other purpose. If color is used inconsistently, then it ceases to have meaning.

| WRONG | |

|

Pump not active. status normal. Color seems to show alarm status. |

|

Pump active. status normal. Color seems to show an abnormal situation. |

very important; "RUN", "START" and "STOP" are commands and are used on buttons. "RUNNING", and "STOPPED" are better texts to present a status.

| BETTER | |

|

Pump not active. Shape not filled and darker then background. |

|

Pump active. Shape filled and lighter then background. |

|

Pump static. Shape filled and matching the background. |

ANSI/ISA-101

Proper alarm depiction should also be redundantly coded based upon alarm priority (color, shape, text). Alarm colors should not be used for non-alarm related functionality.

By using redundantly coded depiction, color blindness is not an obstacle to correctly interpret the condition.

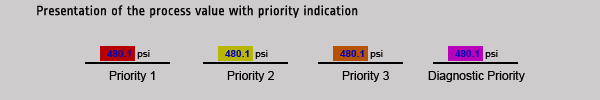

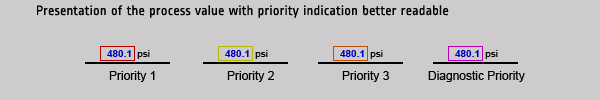

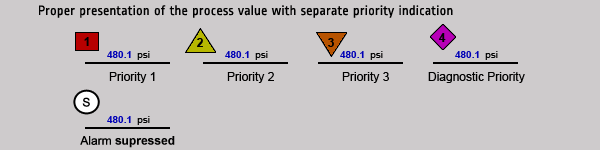

The following figures show several alarm indication methods with their advantages and disadvantages. The third method is the one recommended.

Advantages:

- The color stands out and draws attention to the value in alarm.

- For the unacknowledged condition, flashing of the solid block and not the value ensures the value is always visible.

Disadvantages:

- Color combinations can be problematic – consider the red – blue combination for priority 1.

- The alarm priority is shown only by color and is not redundantly coded, thus the color-blindness issue is involved.

Advantages:

- The color stands out and draws attention to the value in alarm, although the decreased area of colored space provides a lesser effect.

- For the unacknowledged condition, flashing of the outline block and not the value, ensures the value is always visible.

- The color combination problem in the method#1 is addressed.

Disadvantages:

- The alarm priority is still shown only by color and is not redundantly coded, thus the color-blindness issue is still unsolved.

Advantages:

In this method, an alarm indication element appears with the activation of the alarm condition.

- The color stands out and draws attention to the value in alarm with adequate visibility.

- For the unacknowledged condition, flashing of the entire element does not affect the visibility of the process value.

- There is no color combination problem.

- Placement of the indicator is flexible and can be anywhere near the value (although a consistent placement is preferred).

Disadvantages:

- All these methods share one disadvantage: the specific type of alarm is not shown. Unless it is obvious from the operator’s inspection of the process variable, a click to bring up the faceplate may be needed to determine the specific alarm.

ANSI/ISA-101

The presentation of the process as well as the dynamic information needs to be simple, straightforward and consistent. Text instead of symbols, a simple text or abbreviation requires less mental effort than interpreting one of the many symbols or icons.

Control valves and controlled motors are often presented with additional values or output percentage.

Presentation of numeric values shows direct actual information. A tiny bar graph shows an approximate value and is difficult to interpret.

|

|

|

|

Present combined values always consistently, for example first process value, second set point value and finally the output value.

By using color, shape and text consistently the risk of misinterpretation will be nil.

|

|