ANSI/ISA-101

Reactive process operation means intervention (reaction) when abnormal situations occur. In practice, the process proceeds far from optimal and the risk of unplanned stops increases.

Active process operation is required, this means that the operator should be aware of the situation at all times, based on accurate information. By providing actual information, process adjustments can be made before an abnormal situation occurs.

This will result in a smoother production process and generate higher returns and will minimize production stops.

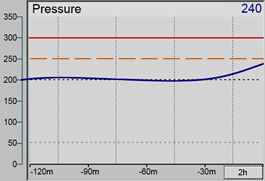

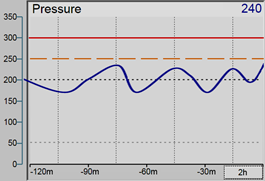

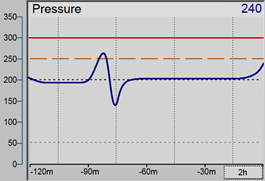

A valuable tool is trending. Using integrated trends one can predict the course of the process and intervene in time if necessary.

The pressure had been stable at the desired 200psi, but began to rise at an even rate an hour ago. If this continues, it will reach the alarm point in a few minutes.

The pressure has been oscillating around the desired value at about a 30 minute rate, but not getting up to the alarm point.

An upset about 90 minutes ago was over-corrected after the alarm. No wit looks like something similar might be beginning to happen again. A simple static display value would not convey any of this important information.

These examples show that the use of trends is very important for active process control, it is also recommended, where possible, to implement trends in process displays.